Etching

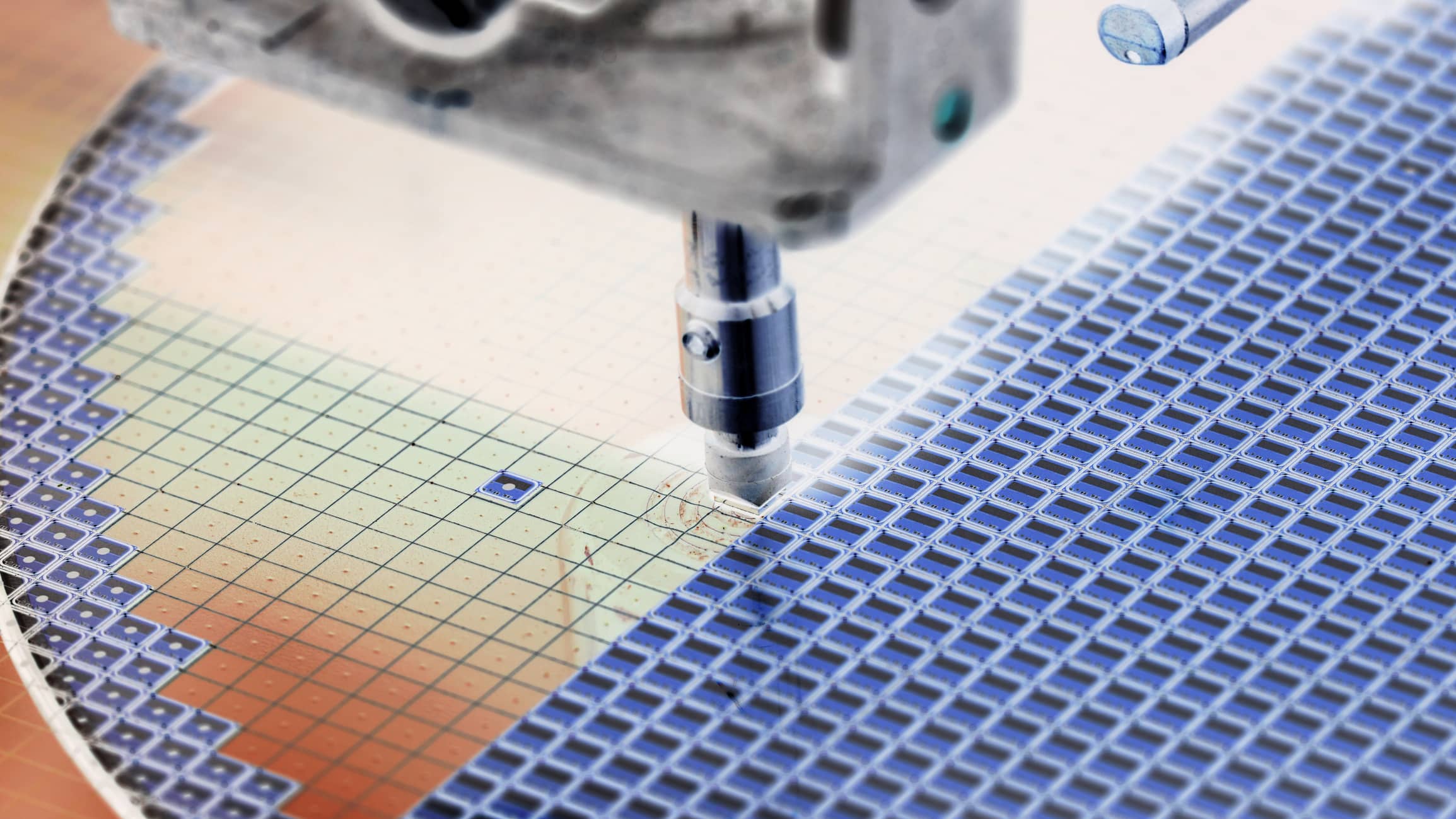

Etching is the chemical removal of a thin film material during device processing. It’s a subtractive process, using either soft or hard masking. We divide etching into two types: dry etch and wet etch. Dry etching uses a plasma-based toolset while wet etching uses a chemical bath in wet benches. With field-proven experience under our belt, we provide either etch variation to meet your requirements.

Dry Etch

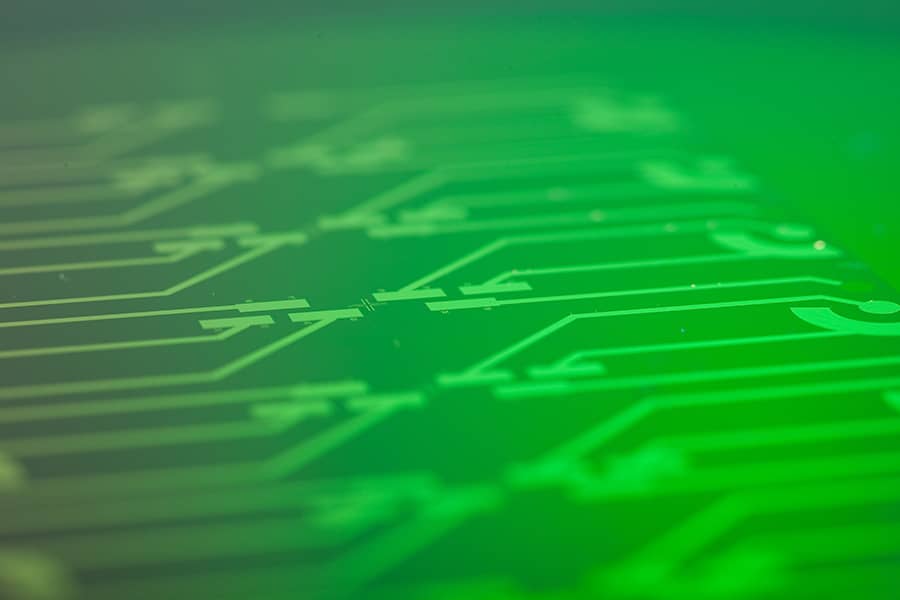

Dry etching uses a plasma-based tool set to chemically remove thin films. Our dry etch is set up for our dielectric films such as silicon nitride, silicon oxide, and silicon oxynitride. Niobium and TiN can also be etched using our dry etch method.

Wet Etch

Wet etching utilizes chemical baths to selectivity etch materials. For silicon, we offer both KOH and TMAH for wet etching options. A buffered oxide etch (BOE) is a solution for oxides. For metals, we offer etchant solutions for gold (Au), chromium (Cr), and aluminum (Al). Not seeing a solution? Do not hesitate to contact us to discuss your requirements.

DRIE

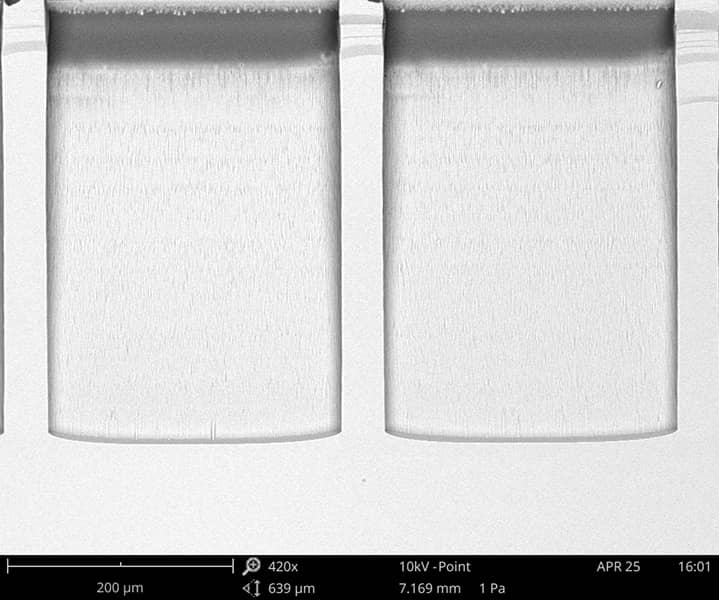

We use the industry-standard deep reactive ion etching (DRIE) to achieve selective silicon etching. DRIE allows for a fast, high-aspect-ratio (20:1) etch with precise feature definition and etch profile-control. The result is a very deep cavity and trench etches with steep, clean sidewalls.

Silicon Etch

Depending on your device requirement, we can complete silicon etching in one of two ways. Wet etching utilizes hard masks of oxide or nitride and results in square features via etching along the silicon planes. Silicon wet etch also provides slanted sidewalls due to the silicon planes.

Dry Passivation Etch

Dry passivation etch uses a plasma-based tool (Reactive Ion Etcher) to chemically remove thin films. Our dry etch uses fluorine-based gases to attain a clean etch of our silicon nitride, silicon oxide, and silicon oxynitride thin films. Let us know your etch stop material when you request a quote as this allows us to select the correct fluorine gas for your passivation layer and etch stop.

Metal Etch

We offer buffered oxide etch (BOE), Au etchant, Cr etchant, and Al etchant. If you’re looking for a different solution, please contact to discuss as we may be able to support other etchants upon request.