Our Services

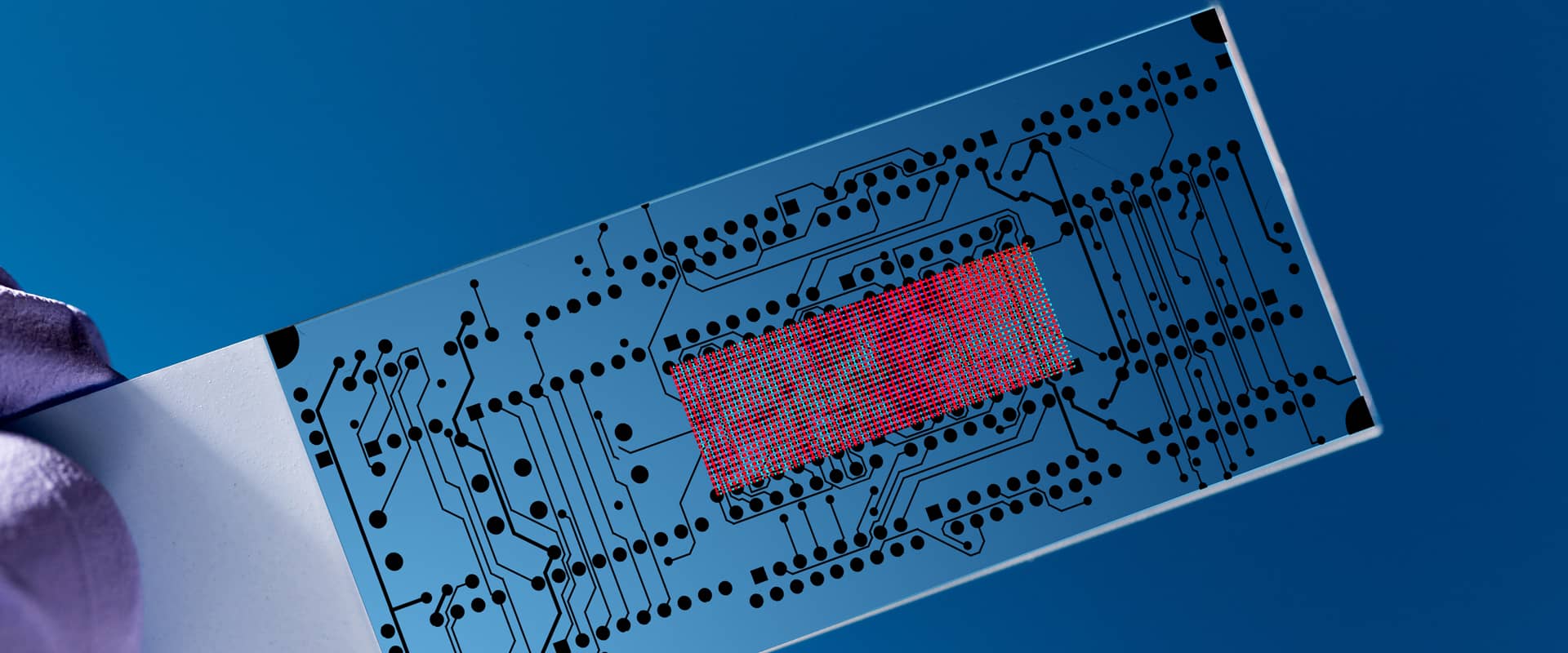

MEMS Foundry

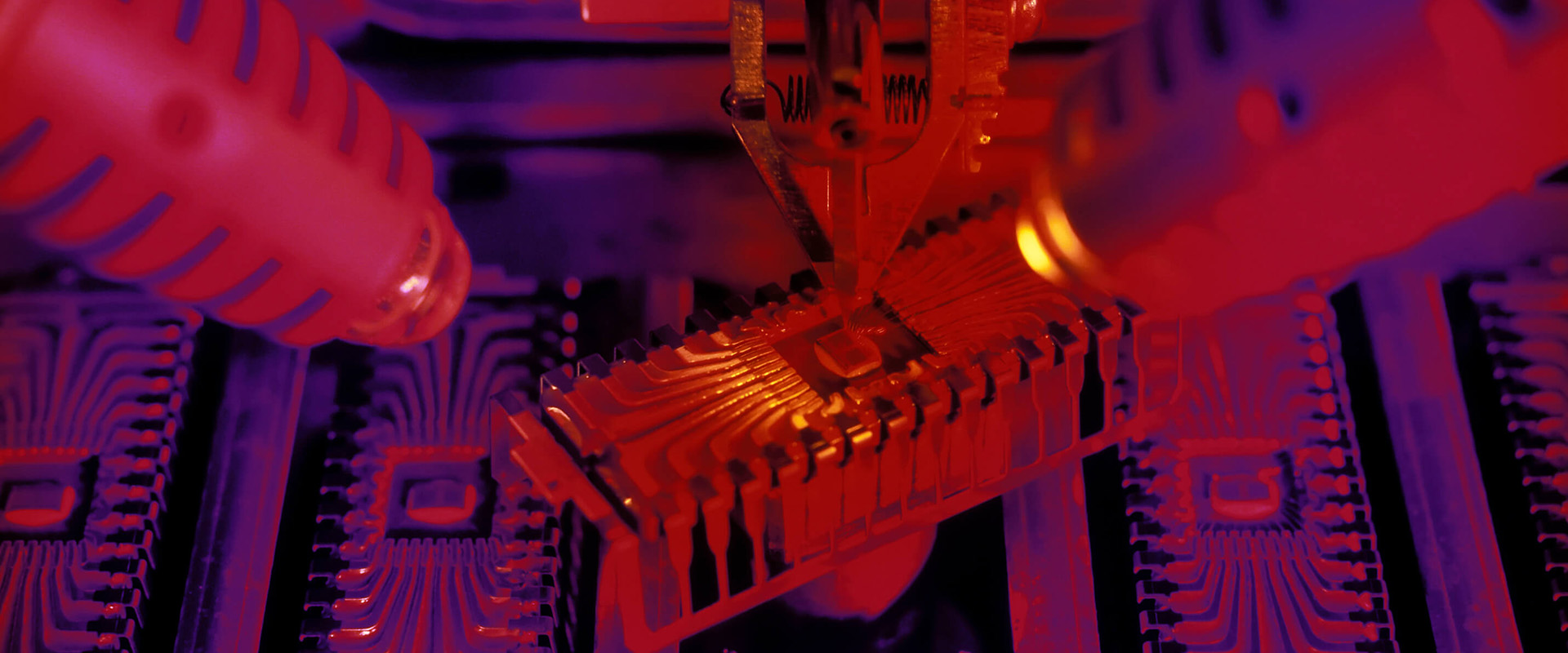

Thin Films

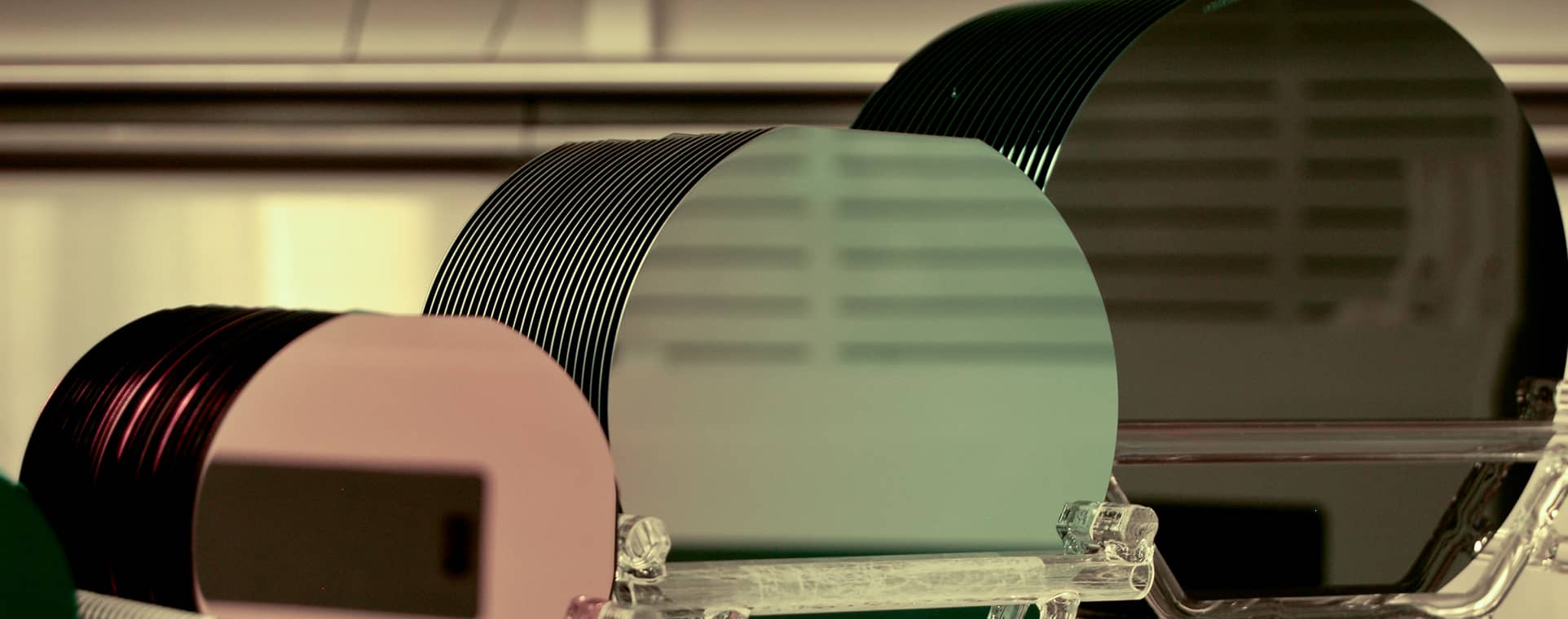

In-stock Wafers

Careers

We’re hiring! Become part of our team.

What could be better than an exciting career helping to build the next cool product? Getting to do it with fun people in a beautiful location. Let’s explore how we can change the world—and your experience in it—by welcoming you to an innovative company in the exciting microelectronics industry.

Ready To Get Started?

The Latest

Rogue Valley Microdevices and C2MI Sign MOU to Offer Fast-Track MEMS Platform Creation and Deployment

News Provided By Rogue Valley Microdevices October 02, 2025, 12:30 GMT Rogue Valley Microdevices team with 300mm wafer Through this MOU, the two organizations will pool expertise and infrastructure to give customers greater access to essential resources. We’re delighted […] Read More »

From Struggling Startup To One-Of-A-Kind Microdevice Manufacturer

When Rogue Valley Microdevices was founded, it couldn’t afford air conditioning. Now, with $6.7 million in CHIPS funding, CEO Gomez is tripling their manufacturing capacity. Jessica Gomez has come a long way in the microchip industry. She is the founder […] Read More »

Global Semiconductor Industry Plans to Invest $400 Billion in 300mm Fab Equipment Over Next Three Years, SEMI Reports

MILPITAS, Calif. — September 26, 2024 — Global spending on 300mm fab equipment is expected to reach a record US$400 billion from 2025 to 2027, SEMI highlighted today in its quarterly 300mm Fab Outlook Report to 2027 report. The robust […] Read More »