Silicon Oxide

Building MEMS devices on top of silicon? You can use thermal oxide as the primary passivation layer when building devices on top of silicon. This allows you to build MEMS devices with the more temperature-friendly silicon rather than glass substrates.

PECVD silicon oxide or silicon oxynitride can serve as a sacrificial layer or temporary hard mask for wet silicon etching, such as TMAH. E-beam oxide is an excellent final passivation layer for protecting the top metal layers from the environment. There are helpful variations of oxide films to support temperature-sensitive substrates. PECVD films allow deposition at a lower temperature and can serve as a dielectric between metal layers, since it supports opening interconnects using etching processing.

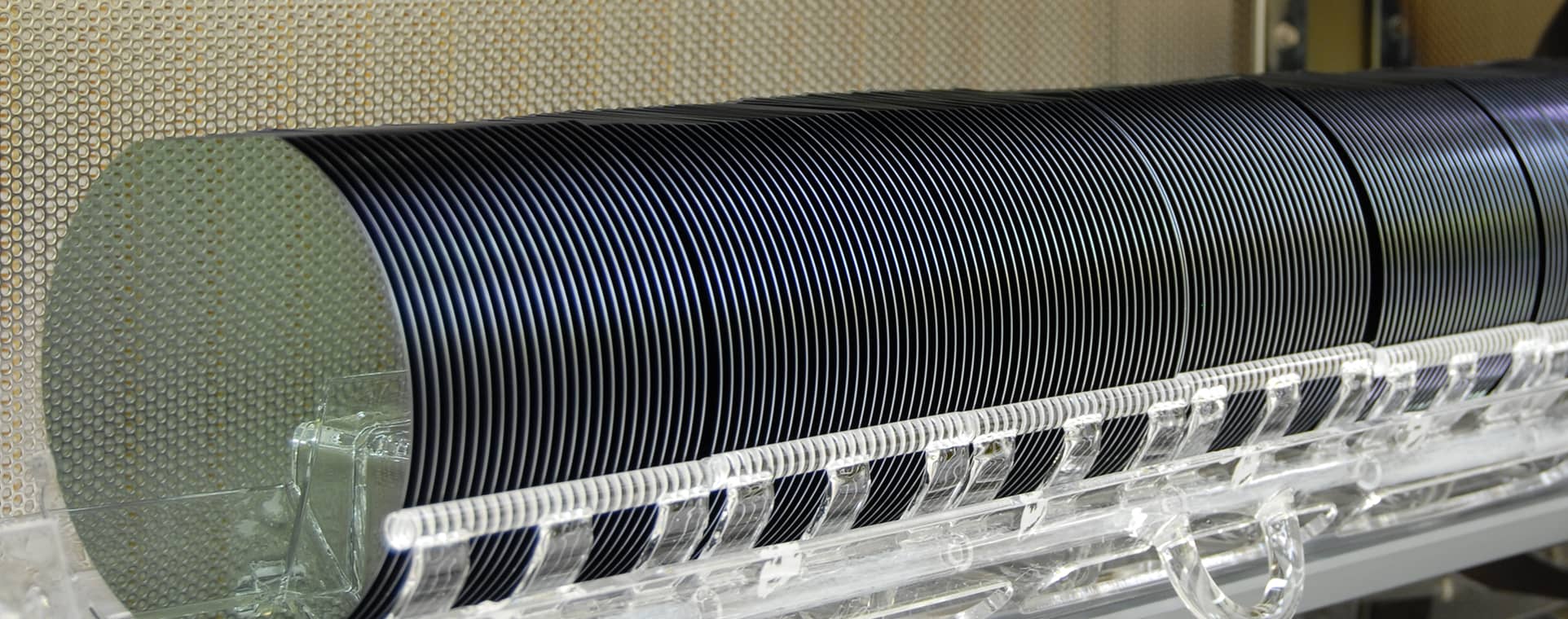

Thermal Oxide

Our ultra-pure thermal oxidation process ensures that you receive the highest-quality films. We can process 50.8mm – 200mm silicon and SOI wafers in our class 100 cleanroom.

Wet Thermal Oxide

Whether you’re using wave guides or silicon-on-insulator (SOI) wafers, protecting your silicon wafer surface, or using it as a hard mask, our wet thermal oxide offers a host of benefits. Film thickness range: 1,000Å to 10µm.

Dry Thermal Oxide

Does your application require a thinner oxide? Our dry thermal oxide could be your best choice. Film thickness range: 100Å to 3,000Å.

Dry Chlorinated Thermal Oxide with a Forming Gas Anneal

Are you using a metal-oxide-semiconductor (MOS) or another active-device fabrication process? Using dry chlorinated thermal oxide can help to eliminate metal ions, enabling your device to achieve its highest level of performance.

A forming gas anneal (FGA) after oxidation lets you passivate any dangling bonds. This is important because dangling bonds at the silicon interface can affect the insulating properties of your oxide. By adding the FGA, you’ll receive the maximum benefit of your dry chlorinated oxide.

Film thickness range: 100Å to 3,000Å.

Flexible on specifications?

We offer silicon wafers with thermal oxide through our stocked ready-to-ship online store.

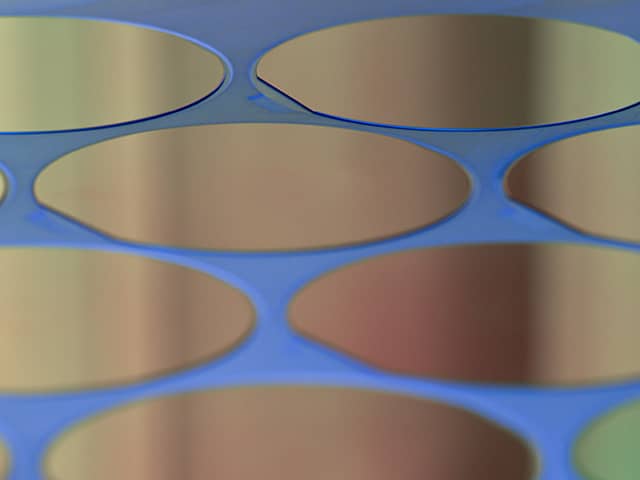

PECVD Oxide

Our PECVD oxide is a silane-based film used for wafers that require minimal thermal processing. Leveraging our proprietary process solution, we offer this film at 200°C up to 375°C. Our low-temperature films are ideal for deposition on glass substrates and temperature-sensitive films. PECVD is a single-side deposition that lets us process 50.8mm-300mm wafers. Film thickness range: 300Å to 4µm.

E-Beam Evaporated Oxide

E-beam evaporation is ideal for processes that require low-temperature oxide deposition under high-vacuum conditions. We can process 100mm, 150mm, and 200mm wafers.

Thermal Anneals

We offer nitrogen, nitrogen/oxygen, and forming gas anneals.

Annealing after deposition can be important if wafers will be exposed to high temperatures later on in the process. Adding an anneal will densify PECVD films making them more stable during thermal cycling.

- Nitrogen (N2) Anneal

- Nitrogen / Oxygen (N2/O2) Anneal

- Oxygen (O2) Anneal

- Forming Gas Anneal (Hydrogen 4% / Nitrogen 96%)