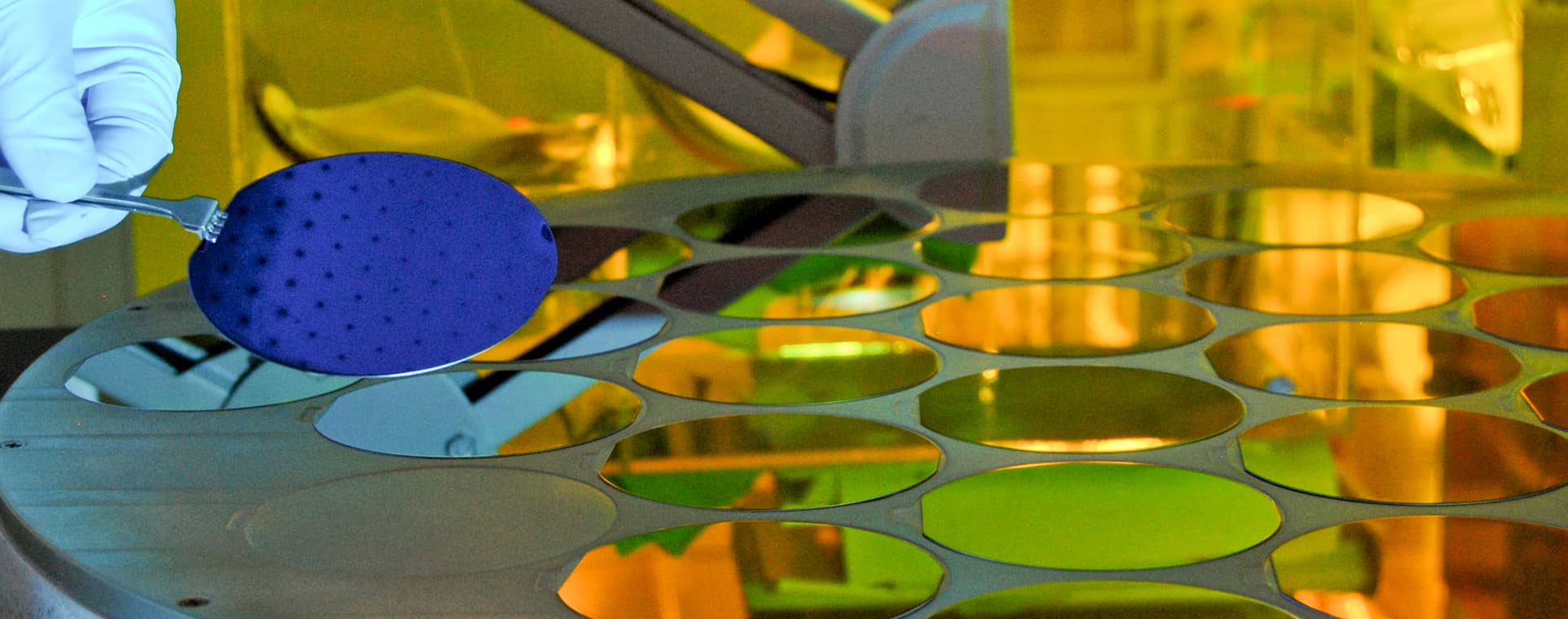

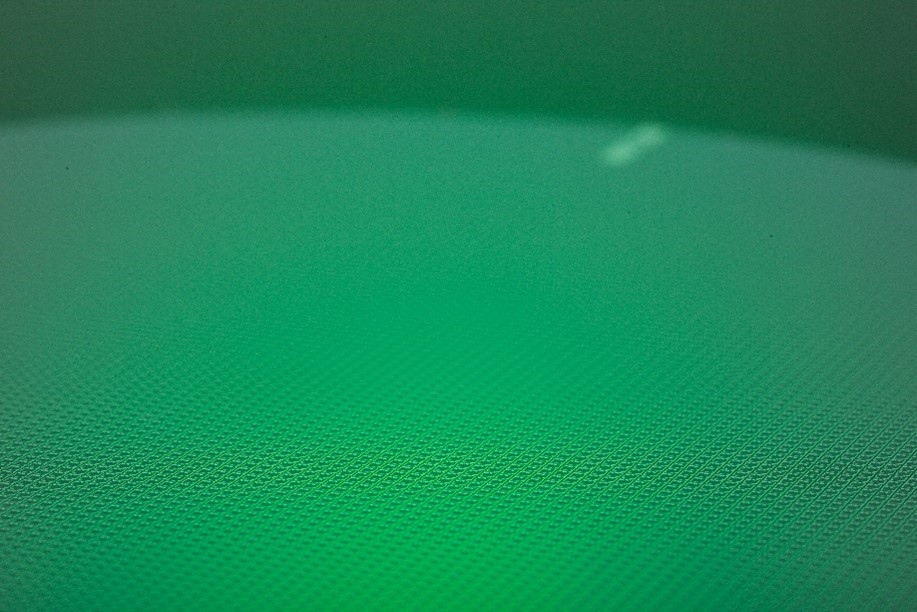

Photolithography

When it comes to MEMS, biomedical devices, and optical sensors, photolithography isn’t one-size-fits-all. Requirements may vary widely, depending on the design and function of your device. We have the capabilities to support you.

MEMS, biomedical devices, and optical devices often require smaller geometries and tighter line widths than a contact aligner can achieve. That’s why we maintain both I-line stepper lithography equipment and contact lithography equipment with front-to-back alignment capability. Our front-to-back contact aligner provides patterning alignment on both the back and front sides of the substrate for your MEMS and biomedical devices.

Contact and Proximity Alignment

- Substrate: 100mm, 150mm, 200mm

- ≥5µm Feature Size

- Front-to-Back Alignment Capability

Projection Alignment (Stepper)

- Substrate: 150mm

- ≥1µm Feature Size

- 5x Reduction Stepper

- Field Step Size 15mmx15mm